Research Uses Nanotechnology to Boost Dietary Value of 3D Printed Foods

Precision 3D printing offers manufacturing advantages for healthy foods

By Fred Miller – Apr. 17, 2023

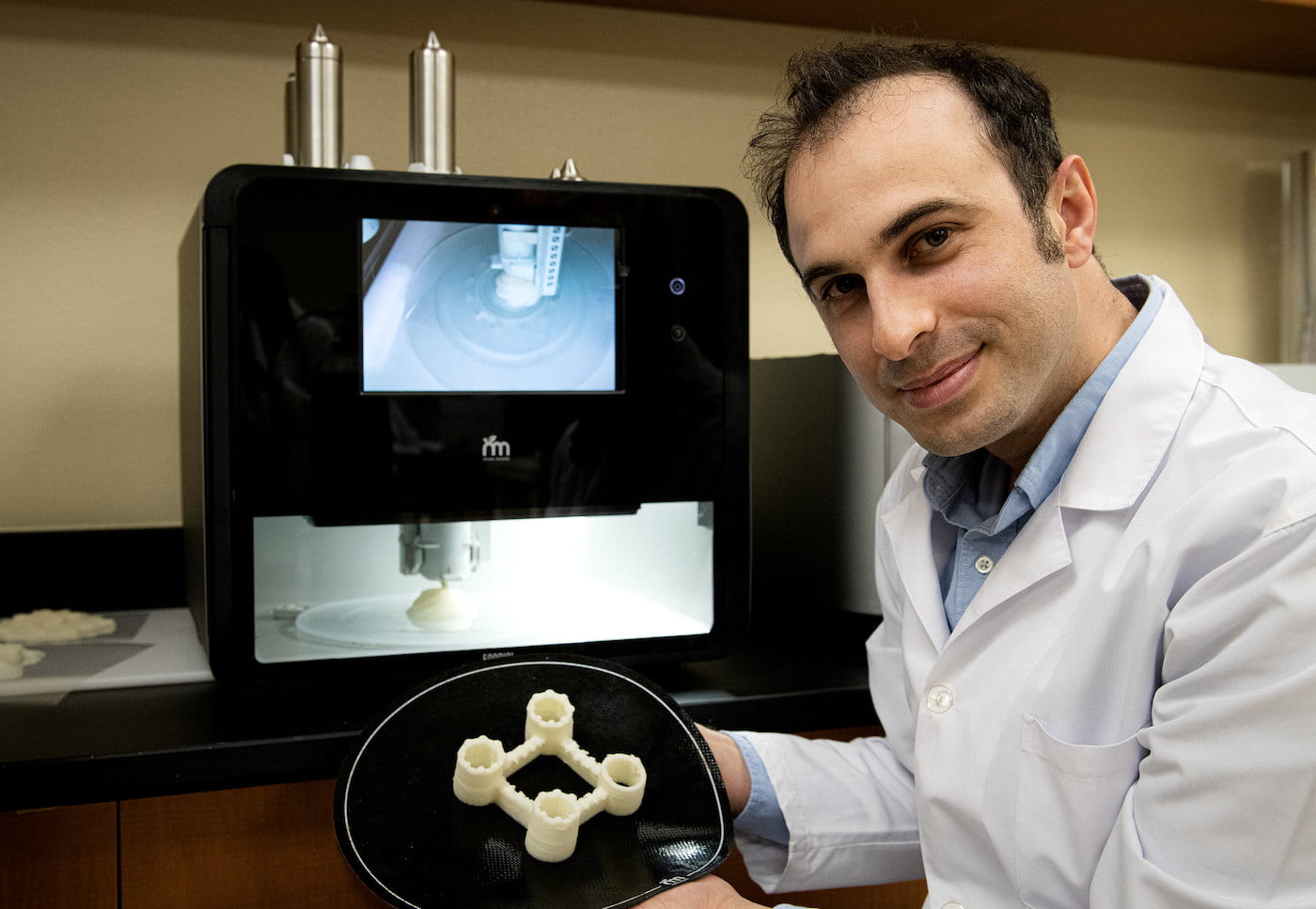

NUTRITION IN 3D — Ali Ubeyitogullari, assistant professor of food engineering, is applying nanotechnology using supercritical carbon dioxide to boost the nutritional value of 3D-printed foods. (U of A System Division of Agriculture photo by Fred Miller)

MEDIA CONTACT

Fred Miller

U of A System Division of Agriculture

479-575-4732 | fmiller@uark.edu

@AgNews479

FAYETTEVILLE, Ark. — Ali Ubeyitogullari is using an advanced nanotechnology to increase the nutritional value of 3D printed foods.

Ubeyitogullari, an assistant professor of food engineering, employs supercritical carbon dioxide to reduce bioactive compounds — naturally occurring chemicals found in foods — to nanoscale particles that are more easily absorbed by tissues in human digestive systems. Bioactive compounds have health benefits beyond their normal nutritional value and are common ingredients in nutritional supplements.

“We work at the intersection of food engineering and human health to improve people’s diets,” Ubeyitogullari said of his research team.

“Bioactive compounds have potential health benefits,” Ubeyitogullari said. “However, they are not absorbed properly in the body. Our research is devising a way to make bioactive compounds easier to absorb and then find a way to incorporate them into everyday food sources.”

Ubeyitogullari is a scientist for the Arkansas Agricultural Experiment Station, the University of Arkansas System Division of Agriculture’s research arm, and a teacher for the University of Arkansas’ Dale Bumpers College of Agricultural, Food and Life Sciences.

Absorption and stability issues

Earlier research has demonstrated how bioactive compounds extracted from fruits or vegetables can be infused into other foods or drinks to improve their health benefits.

The problem with bioactive compounds, Ubeyitogullari said, is that they often are not readily available to human digestion systems. Most of the nutritional value is wasted without being fully absorbed in the body.

In part, this is because the bioactive compounds generally have crystalline structure and are water-insoluble, making them hard and difficult for digestive systems to break down and absorb them.

The compounds also have poor chemical stability. They lose effectiveness quickly, shortening their shelf life for retail storage and shipping.

Improving function

To address these issues, Ubeyitogullari employs supercritical carbon dioxide. Carbon dioxide gas is subjected to high pressure — ranging from 1,450 pounds per square inch to 5,786.8 PSI — at mild temperatures — 104 degrees to 140 degrees Fahrenheit — to render carbon dioxide in a supercritical state. In this form it behaves like a liquid and gas mixture.

Ubeyitogullari uses supercritical carbon dioxide to prepare the bioactive compounds, reducing them to nanoscale and drying them in a form that avoids crystallization.

He also uses supercritical carbon dioxide to create a porous material from corn starch, a digestible biopolymer, that he uses to encapsulate the bioactive compounds. The process breaks down surface tension during drying to prevent shrinkage, resulting in nanoporous structure.

A nanometer is metric unit equal to one-billionth of a meter. Ubeyitogullari said he reduces the bioactive compounds to as small as 50 nanometers. A sheet of paper is about 100,000 nanometers thick, and a human hair is between 80,000 and 100,000 nanometers thick.

Precision 3D printing loads the nanoscale bioactive compounds into the starch biopolymer to fabricate beads that are suitable for use in nutrition supplements or 3D printed foods. The process also makes them stable up to 21 days at up to 122 degrees Fahrenheit. “That’s a significant improvement in shelf life,” he said.

To assess how the still experimental formation affects body absorption, Ubeyitogullari is simulating digestion in the lab to see if the supercritical carbon dioxide process makes the products more available to human tissue than freeze-drying. The tests involve dissolving the biopolymer-encapsulated particles in an artificial medium that simulates digestion.

If it tests well, Ubeyitogullari said the next step is an in vitro test in collaboration with Sun-Ok Lee, associate professor of nutrition for the Agricultural Experiment Station. That research will help confirm the transfer of nutritional value to human cells.

MEDIA CONTACT

Fred Miller

U of A System Division of Agriculture

479-575-4732 | fmiller@uark.edu

@AgNews479

3D printing

Ubeyitogullari said 3D printing offers several advantages over traditional manufacturing methods. “It allows us to precisely control the amount of bioactive compounds used in a product,” he said. “And it offers precise control of where they will be located within a food matrix.”

The system would also be more flexible than current manufacturing technology, Ubeyitogullari said. An existing manufacturing line requires a complete shutdown and complex reformatting of the manufacturing equipment to change from making one product to another.

A 3D printing system can be reset for another product by simply changing the printing cartridges and selecting a different computer program to run it, he said.

Ubeyitogullari said health-promoting bioactive compounds could one day be infused directly into 3D printed foods. For now, that would likely be cookies or candy, products he often prints for teaching and demonstrations.

But he envisions a system where people can select a meal from a menu on their smart device, add nutritional supplements or medicines and send it to the printer. It could be ready to eat when they get home from work.

Next steps

Ubeyitogullari is applying the same technology to improve delivery of probiotics — beneficial bacteria that have many health benefits — to the intestinal tract.

Probiotic products in pill form can be convenient interventions to restore gut health. But, like bioactive compounds, probiotics have limited shelf life, Ubeyitogullari said. Also, they can be destroyed or diminished in transit through the stomach, where digestive acids create a very hostile environment for the probiotic microbes.

Ubeyitogullari is developing a means of infusing probiotic microbes in porous alginate-pectin media — another edible biopolymer — that can protect them in the digestive tract. Alginate is a seaweed extract and pectin is the gel in jellies. The alginate-pectin material is resistant to low pH (highly acidic) levels in stomach acids but will open in the less acidic levels found in the colon.

To learn more about the Division of Agriculture research, visit the Arkansas Agricultural Experiment Station website. Follow us on 𝕏 at @ArkAgResearch, subscribe to the Food, Farms and Forests podcast and sign up for our monthly newsletter, the Arkansas Agricultural Research Report. To learn more about the Division of Agriculture, visit uada.edu. Follow us on 𝕏 at @AgInArk. To learn about extension programs in Arkansas, contact your local Cooperative Extension Service agent or visit uaex.uada.edu.

About the Division of Agriculture

The University of Arkansas System Division of Agriculture’s mission is to strengthen agriculture, communities, and families by connecting trusted research to the adoption of best practices. Through the Agricultural Experiment Station and the Cooperative Extension Service, the Division of Agriculture conducts research and extension work within the nation’s historic land grant education system.

The Division of Agriculture is one of 20 entities within the University of Arkansas System. It has offices in all 75 counties in Arkansas and faculty on three campuses.

Pursuant to 7 CFR § 15.3, the University of Arkansas System Division of Agriculture offers all its Extension and Research programs and services (including employment) without regard to race, color, sex, national origin, religion, age, disability, marital or veteran status, genetic information, sexual preference, pregnancy or any other legally protected status, and is an equal opportunity institution.