Experimenting with CO2 Sensors for Grain Bin Quality Control

Carbon dioxide sensors investigated as added tool for grain bin monitoring

By John Lovett – Mar. 11, 2024

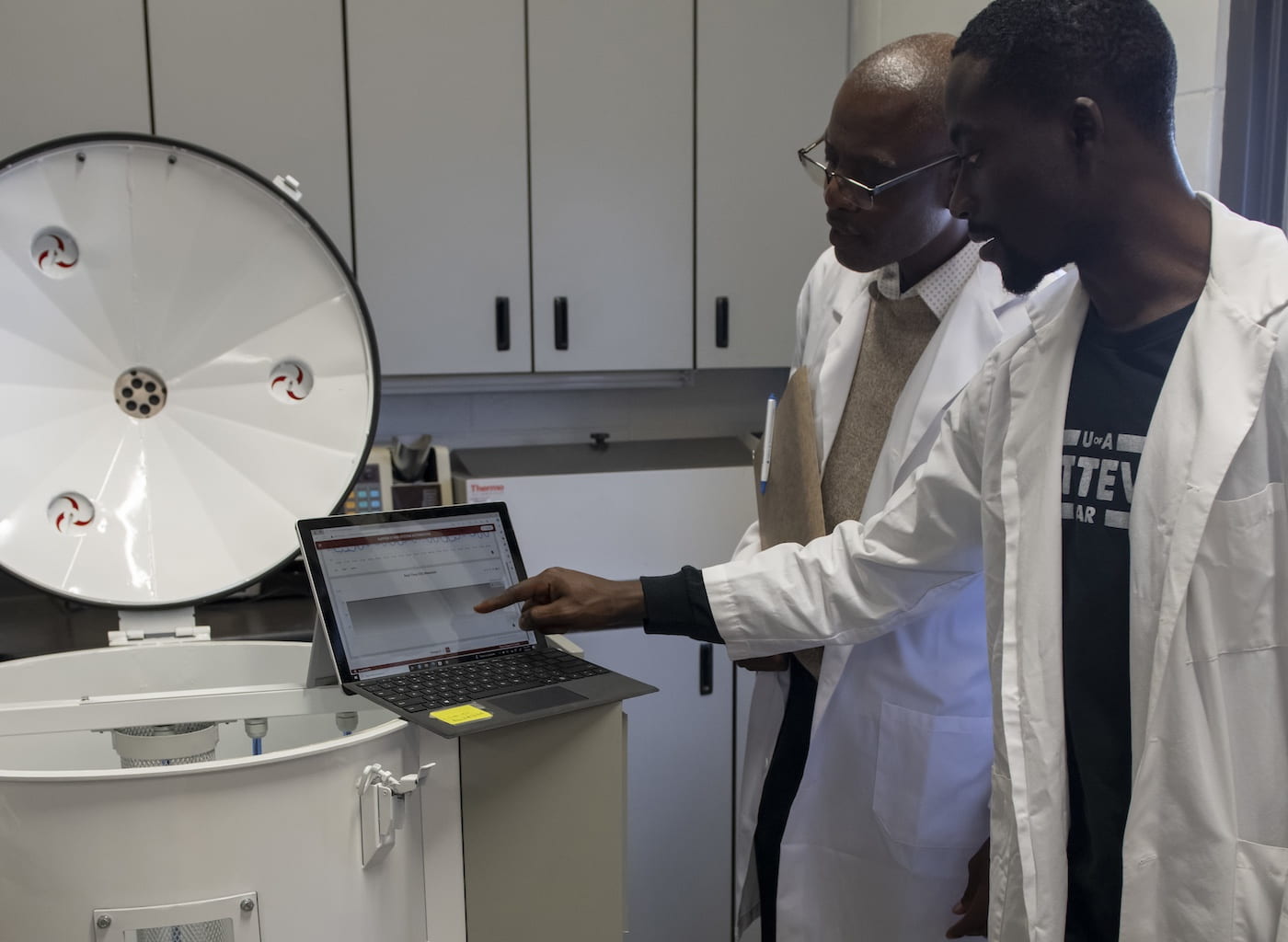

CARBON DIOXIDE SENSORS — Griffiths Atungulu, left, director of the Rice Processing Program, works with Samuel Olaoni, Ph.D. student, on a miniature grain bin to test carbon dioxide sensors for monitoring grain quality. (U of A System Division of Agriculture photo)

FAYETTEVILLE, Ark. — Sinking Mississippi River levels in recent years have caused grain shipping disruptions, prompting farmers to pursue on-farm grain bins to preserve quality and market potential.

“Storage is becoming a critical thing,” said Griffiths Atungulu, director of the Rice Processing Program for the University of Arkansas System Division of Agriculture. “Even in just the Delta, the farmers I visit every year have added one bin, and some of them have doubled their number of bins. That tells me how critical it is becoming for them to have their own storage.”

The Rice Processing Program aims to help farmers maximize the value of their stored rice by developing recommendations for reducing moisture and monitoring quality. To that end, Atungulu has recently begun experimenting with carbon dioxide sensors to improve on-farm grain bin quality control.

Atungulu is an associate professor of food science for the Arkansas Agricultural Experiment Station, the research arm of the Division of Agriculture. As an agricultural engineer, he specializes in grain processing and post-harvest system engineering.

Temperature and moisture sensors attached to thin cables hanging from a grain bin’s roof are currently the most advanced monitoring system for on-farm grain bins. Carbon dioxide sensors have the potential to serve as a relatively inexpensive upgrade to go with the cables, Atungulu says.

He hypothesizes that carbon dioxide sensors can detect the presence of mold and insect pests in rice before they become a significant problem. However, the temperature sensors on the cables help determine the area in the grain bin where the abnormality is located. A farmer could decide whether to move out all the grain or just a portion.

Upgrading technology

The cable systems that now serve as the bin’s moisture and temperature sensors aren’t perfect. The force that grain places on them creates the potential to collapse a grain bin’s roof. The temperature and moisture sensors on cables are also prone to being clogged by dust and can malfunction over time.

In the future, Atungulu envisions adapting high-frequency wavelength technologies to detect temperature and moisture.

“Our research is focused on what we can do to make sure that rice, when it comes in at a higher moisture content, is dried effectively, the best way possible, and then after drying it, the quality of that rice can still be maintained,” Atungulu said.

Atungulu has previously conducted extensive research on calibrating temperature probes on cables, predicting temperature changes in grain bins, and guidelines for drying rice in on-farm bins for storage.

MINI BIN — A miniature grain bin made by Garten Automation in Brazil is used to study the use of carbon dioxide sensors as an added tool for grain quality control. (U of A System Division of Agriculture photo)

Mini grain bin from Brazil

A miniature grain bin, about the size of a residential water heater tank, is currently housed at the experiment station’s food science pilot plant in Fayetteville. Built by Garten Automation in Brazil, the little grain bin has a carbon dioxide sensor at the top, temperature sensors on simulated steel cables, and a control panel that allows for remote computer monitoring. A false bottom and air inlet also allow for a fan for drying.

Atungulu toured rice processing facilities in Brazil’s Rio Grande do Sul area last year. He also presented on American rice processing research as the international guest speaker at the Conecta Grano Safe 2023 conference.

University of Arkansas Ph.D. student Samuel Olaoni is conducting experiments on the mini grain bin to test for correlations between temperature and carbon dioxide increases and relationships between insect growth and carbon dioxide dynamics.

“The carbon dioxide sensors look promising, but they can’t stand alone because they can’t tell us exactly where the problem is,” Atungulu said. “Integrating both the cables and the carbon dioxide sensors can move the industry in a better direction than just having one system.”

Eventually, Olaoni and Atungulu can look at how the grain quality changes with those insect and carbon dioxide dynamics.

To learn more about the Division of Agriculture research, visit the Arkansas Agricultural Experiment Station website. Follow us on 𝕏 at @ArkAgResearch, subscribe to the Food, Farms and Forests podcast and sign up for our monthly newsletter, the Arkansas Agricultural Research Report. To learn more about the Division of Agriculture, visit uada.edu. Follow us on 𝕏 at @AgInArk. To learn about extension programs in Arkansas, contact your local Cooperative Extension Service agent or visit uaex.uada.edu.

About the Division of Agriculture

The University of Arkansas System Division of Agriculture’s mission is to strengthen agriculture, communities, and families by connecting trusted research to the adoption of best practices. Through the Agricultural Experiment Station and the Cooperative Extension Service, the Division of Agriculture conducts research and extension work within the nation’s historic land grant education system.

The Division of Agriculture is one of 20 entities within the University of Arkansas System. It has offices in all 75 counties in Arkansas and faculty on three campuses.

Pursuant to 7 CFR § 15.3, the University of Arkansas System Division of Agriculture offers all its Extension and Research programs and services (including employment) without regard to race, color, sex, national origin, religion, age, disability, marital or veteran status, genetic information, sexual preference, pregnancy or any other legally protected status, and is an equal opportunity institution.

MINI BIN — A miniature grain bin made by Garten Automation in Brazil is used to study the use of carbon dioxide sensors as an added tool for grain quality control. (U of A System Division of Agriculture photo)