Parboiling with Reduced Water Improves Nutrient Content of Rice

The Problem

Rice is a staple food for billions of people around the world. However, micronutrient deficiency disorders are widespread in predominantly rice-consuming locations, especially in South Asia and Africa. Micronutrients like iron, calcium, folic acid and vitamin A play important roles in human health. Iron is a key component of blood’s hemoglobin, which carries oxygen around the body. Calcium helps fight osteoporosis, high blood pressure and colon cancer. Inadequate intake of folic acid is associated with the risk of giving birth to infants with birth defects. Vitamin A deficiency can weaken the immune system and cause delayed growth in children. Fortifying rice with essential nutrients could help improve health for its consumers.

Graduate student Annegret Jannasch, working with food science professor Ya-Jane Wang, investigated a low-cost method to fortify rice by parboiling without changing customer eating habits or requiring extensive technology investments, and with a goal to reduce wastewater impact from parboiling.

The Work

Existing fortification technologies, such as dusting the grains with a nutrient powder, adding a waxy coating of nutrients, and extrusion of reconstituted grains, all have significant drawbacks in retaining the added nutrients through cooking. They also lack consumer acceptance because of taste, color or texture.

It’s estimated that 15 to 20 percent of the world’s milled rice is consumed as parboiled rice. Therefore, fortification by parboiling could be an excellent tool to deliver micronutrients to a large number of people. However, parboiling has a significant drawback because it uses large amounts of water during the process of soaking the grains, then by steaming, drying and milling. Untreated wastewater disposal can also result in nutrient overload in soil, presenting another serious environmental concern.

Jannasch and Wang developed a limited-water soaking method using vacuum packaging. To evaluate the method’s effectiveness, they analyzed the fortified rice quality attributes, micronutrient content and wastewater impacts, and compared these results to rice fortified by traditional parboiling with excess water.

The Results

The limited-water soaking method by vacuum packaging successfully produced fortified rice with minimal impact on rice quality attributes. Simultaneously fortifying rice with iron, calcium, folic acid and vitamin A was found to increase the content of those nutrients in parboiled rice to a level near the levels prescribed by the U.S. Food and Drug Administration for fortified rice. Additionally, the limited-water soaking method reduced overall water usage in the soaking step by 75 percent, resulting in an 89 percent reduction in wastewater on average and a reduction in the amount of total solids in wastewater by up to 85 percent.

The Value

The results of this study validate the limited-water soaking method by vacuum packaging as a way to fortify rice with increased micronutrients and reduce wastewater resulting from traditional parboiling methods. The team is currently working on the scale-up of the process from laboratory to commercial production. Oxfam International, a global organization focusing on alleviating global poverty, is funding a project to scale up this process in Burkina Faso, Africa to help them adapt this fortification process to local parboiled rice production processes.

As this method is optimized and incorporated into commercial operations, it has the potential to give more consumers access to rice with enhanced micronutrient content without changing their eating habits. The reduction in water usage and wastewater production projected by this method makes for a more sustainable parboiling process. And commercial operators have the potential to save money on freshwater input costs and wastewater treatment while providing added value to their customers.

Funding

Arkansas Biosciences Institute

University of Arkansas System Division of Agriculture

About the Researcher

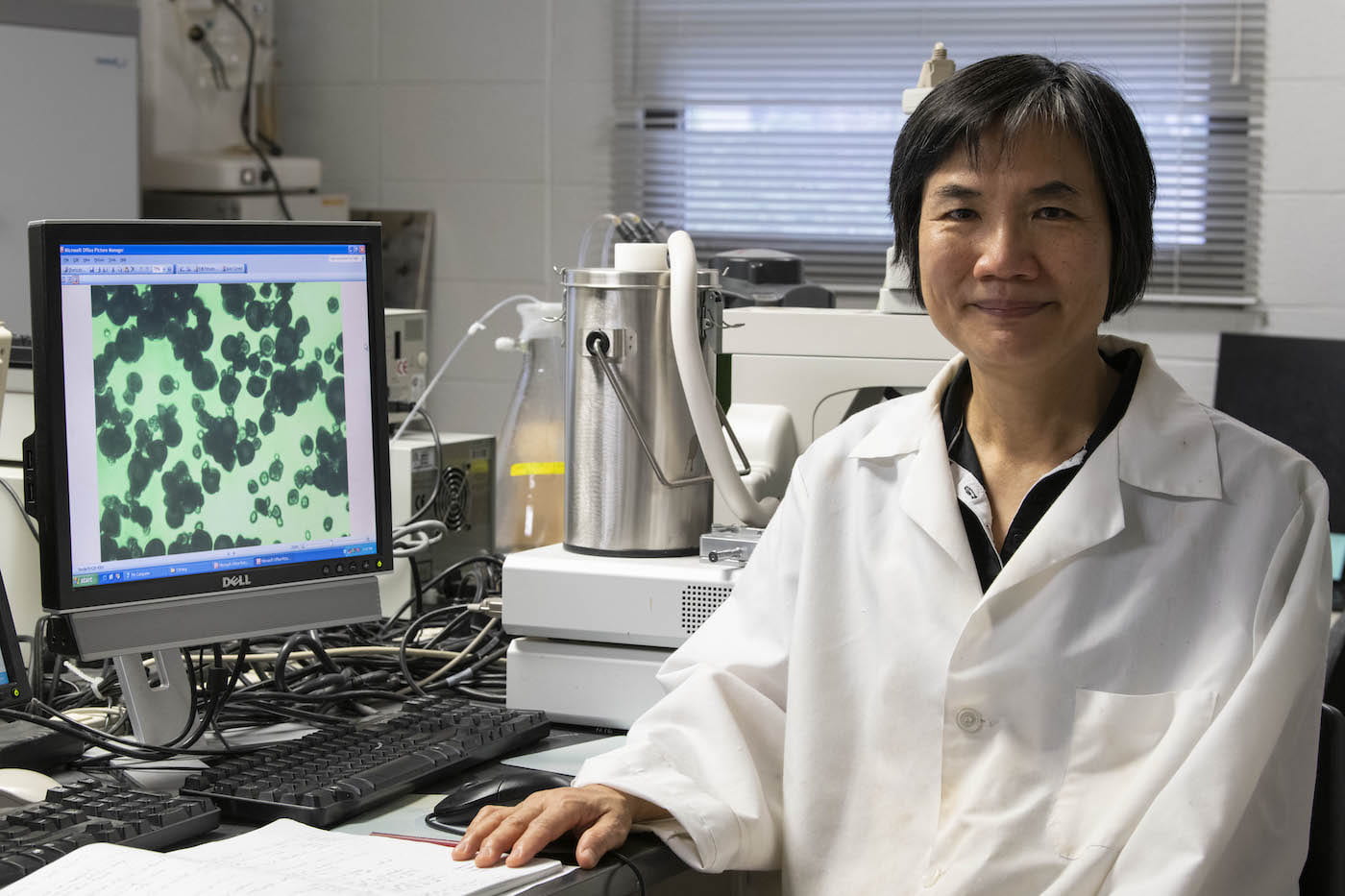

Ya-Jane Wang

Professor of Food Science

- B.S. in agricultural chemistry from National Taiwan University, M.S. in food science and nutrition from the University of Minnesota, and Ph.D. in food science and technology from Iowa State University.

- As supervisor of the carbohydrate chemistry program, Wang specializes in research that seeks to further the use and improve the performance of carbohydrate-rich bioresources. By developing a better understanding of carbohydrate structure and function, the program team’s goal is for carbohydrates to be better utilized in food, pharmaceutical, and industrial applications.

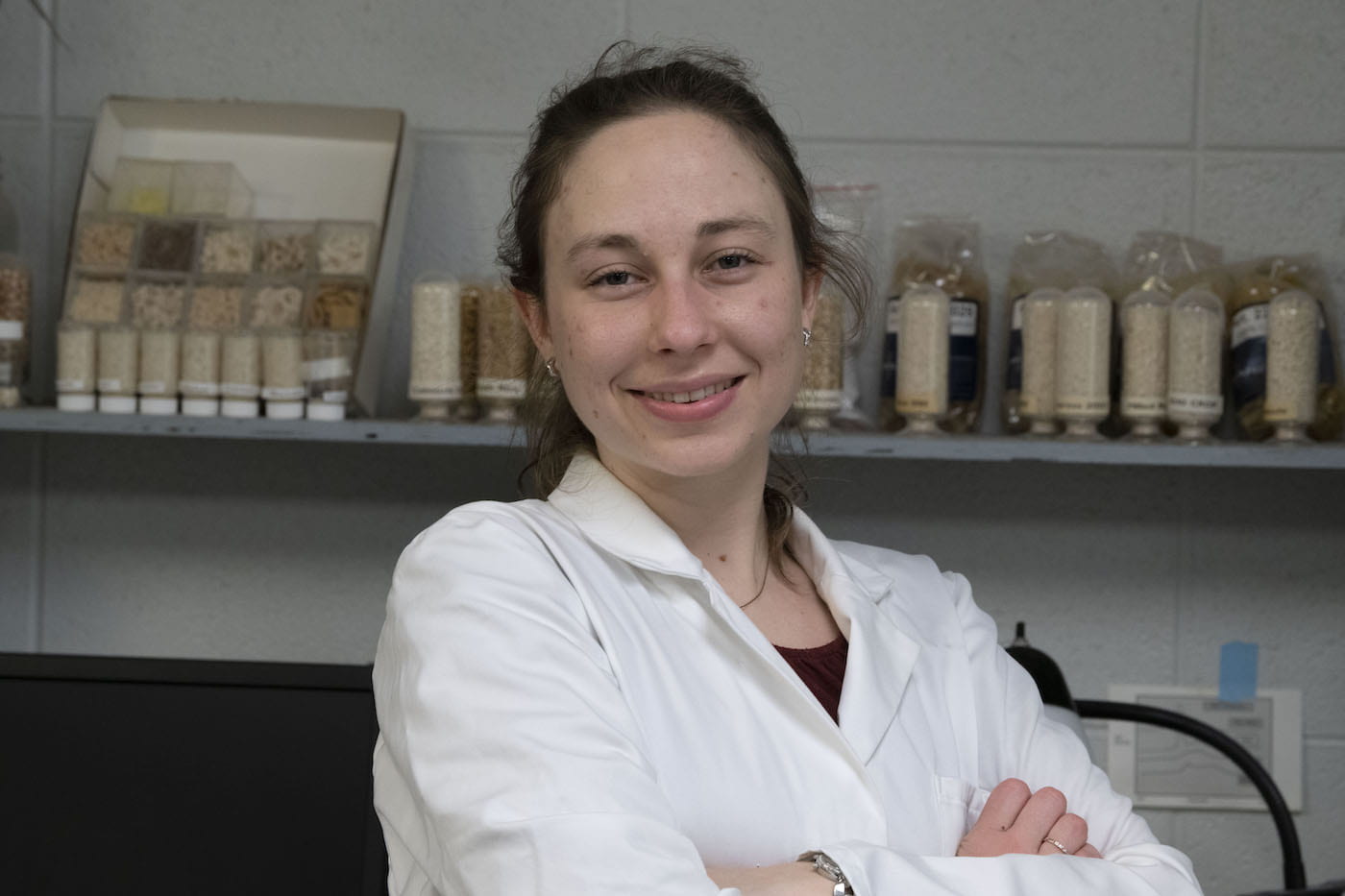

Annegret Jannasch

- Pursuing Ph.D. in Food Science at the University of Arkansas

- B.S. in food science and technology from Fachhochschule Weihenstephan Freising, M.S. in food science from the University of Arkansas