Sorghum Protein Becomes Building Block for 3D-Printed Foods

Materials used as “ink” in 3D food printing applications are often hydrophilic, making them poor carriers of hydrophobic ingredients, like fat-soluble vitamins. To address this problem, food engineers with the Arkansas Agricultural Experiment Station have demonstrated that grain sorghum proteins could be the answer. In a recent study, the researchers found that grain sorghum’s hydrophobic properties make it uniquely suited for printing cohesive, stable structures. The work advances the science of 3D food printing and represents another step on the path to a flexible bioink that can be used to encapsulate medicine or nutrients.

The Problem

Many “bioink” materials used in 3D food printing are hydrophilic, meaning they readily absorb water. This limits their ability to incorporate hydrophobic ingredients, like healthy oils, fat-soluble vitamins, or certain bioactive compounds, without losing structural integrity. These limitations highlight the need for a sustainable, low-cost material ideal for printing and encapsulating nutrients or medicines without collapsing or spreading.

The Work

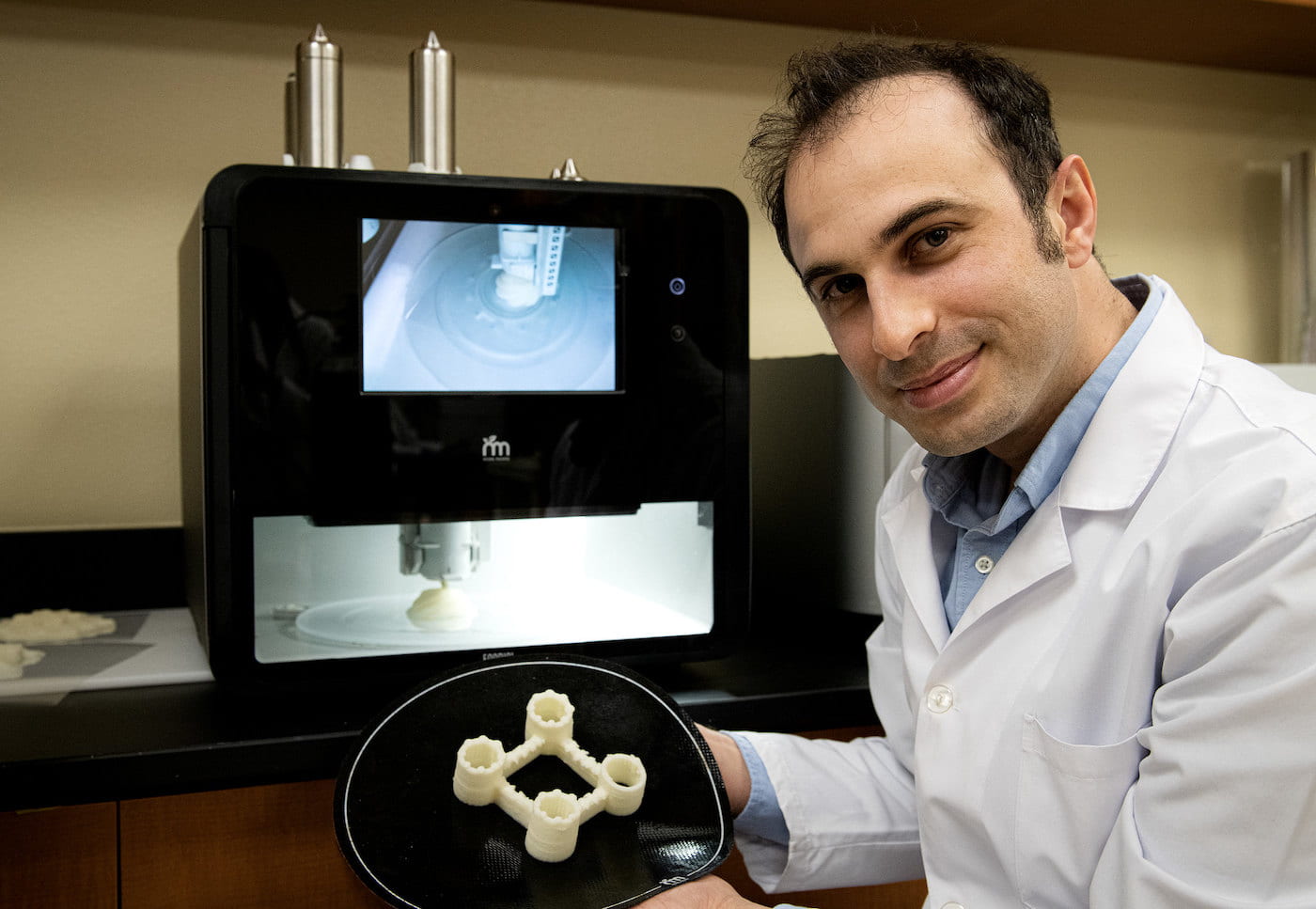

Ali Ubeyitogullari, Assistant Professor of Food Engineering with the Arkansas Agricultural Experiment Station, and postdoctoral fellow Sorour Barekat in the Department of Food Science, optimized sorghum proteins for 3D printing by adjusting protein concentration, nozzle size, and printing speed. Their study, published in the International Journal of Biological Macromolecules, tested various gel formulations and found that a composition of 25% sorghum protein, printed at 20 millimeters per second with a 0.64-millimeter nozzle, achieved the best results. Higher protein concentrations did not improve printability, suggesting that fine-tuning texture and flow behavior, rather than simply increasing protein content, is key to successful printing.

The Results

The researchers produced a novel 3D-printable sorghum protein gel capable of forming intricate and stable structures. Due to its hydrophobic nature, the gel provides cohesion and enables the encapsulation of hydrophobic nutrients or pharmaceutical compounds. This research marks the first successful use of sorghum protein bioink, laying the foundation for its future use in both food design and drug delivery applications.

The Value

Sorghum offers a climate-resilient, sustainable, and gluten-free alternative protein source for 3D printing technologies. Its successful adaptation as a printable bioink could allow for future applications, including nutrient and pharmaceutical encapsulation and delivery.

Read the Research

Maximizing sorghum proteins printability: Optimizing gel formulation and 3D-printing parameters to develop a novel bioink

International Journal of Biological Macromolecules

Volume 300 (2025)

https://doi.org/10.1016/j.ijbiomac.2025.140245

Supported in part by

United Sorghum Checkoff Program; U.S. Department of Agriculture-National Institute of Food and Agriculture, AFRI Award No. 2023-67022-40164; and Arkansas Biosciences Institute for rheometer acquisition support.

About the Researchers

Ali Ubeyitogullari

Assistant Professor

Ph.D. in Food Science and Technology, University of Nebraska-Lincoln

M.S. in Food Engineering, Middle East Technical University in Ankara, Turkey

B.S. in Food Engineering, Middle East Technical University in Ankara, Turkey

Other Collaborators

Sorour Barekat, a postdoctoral fellow in the Department of Food Science, was the lead author of the article.